Selecting the right laboratory glove box is a critical decision for any research facility or laboratory. The glove box plays a crucial role in ensuring the safety of both the operator and the materials being handled. Whether you are working with sensitive materials, conducting experiments in a controlled atmosphere, or handling hazardous substances, choosing the right glove box is essential. This guide, provided by Cleatech LLC, will walk you through the key factors to consider when selecting a laboratory glove box that suits your specific needs.

Define Your Application Requirements

Before diving into the technical details of glove boxes, it’s essential to clarify your specific application requirements. Consider the following questions:

What type of materials will you be handling inside the glove box?

Do you need to work in a controlled atmosphere, such as inert gases or cleanroom conditions?

Are you working with hazardous chemicals that require specific containment features?

Will you need a single-user or multi-user glove box?

What size and workspace configuration do you require?

Having a clear understanding of your application needs will help you narrow down your options and make an informed choice.

Understand the Different Types of Glove Boxes

There are several types of glove boxes available, each designed for specific applications. Here are some common types:

Standard Glove Boxes

Standard glove boxes are versatile and suitable for a wide range of applications. They typically offer a controlled environment, which can be adjusted to maintain specific conditions such as temperature, humidity, or gas composition. Standard glove boxes are a good choice for general research and experimentation.

Controlled Atmosphere Glove Boxes

If you need to work with materials that are sensitive to oxygen or moisture, a controlled atmosphere glove box may be necessary. These glove boxes provide precise control over gas composition, allowing you to create an oxygen-free or moisture-free environment. They are commonly used in industries like electronics, pharmaceuticals, and materials science.

Isolation Glove Boxes

Isolation glove boxes are designed for handling hazardous materials, such as toxic chemicals or biological agents. They provide a high level of containment and protect operators from exposure to dangerous substances. These glove boxes often have specialized filtration systems and additional safety features.

Dry Glove Boxes

Dry glove boxes are used when working with materials that must be kept dry and free from moisture contamination. They are commonly used in applications like semiconductor manufacturing and battery research. Dry glove boxes maintain extremely low humidity levels.

Cleanroom Glove Boxes

Cleanroom glove boxes are essential for applications that require a controlled, particle-free environment, such as semiconductor fabrication or pharmaceutical manufacturing. These glove boxes are designed to meet strict cleanroom standards and prevent contamination.

Consider Glove Material and Configuration

The gloves used in glove boxes come in various materials, each with its unique properties:

Butyl Rubber Gloves

Butyl rubber gloves are highly chemical-resistant and provide excellent protection against a wide range of chemicals. They are suitable for handling hazardous materials but may not be as comfortable for extended use.

Neoprene Gloves

Neoprene gloves are resistant to acids, bases, and many organic solvents. They offer good tactile sensitivity and are often chosen for general-purpose glove boxes.

Nitrile Gloves

Nitrile gloves are latex-free and offer excellent resistance to punctures and chemicals. They are a popular choice for laboratories due to their comfort and versatility.

Hypalon Gloves

Hypalon gloves are known for their resistance to ozone, strong acids, and oxidizing agents. They are suitable for specialized applications that require high chemical resistance.

Polyurethane Gloves

Polyurethane gloves are a cost-effective option, providing decent chemical resistance for less demanding applications.

The configuration of the gloves is also crucial. Some glove boxes offer single gloves, while others have double gloves for added safety and protection. Consider your comfort, dexterity, and the level of protection required when choosing the glove configuration.

Evaluate Workspace Size and Layout

The size and layout of the glove box should match your workspace and workflow. Consider the following factors:

Workspace Dimensions

Determine the size of the materials or equipment you will be working with inside the glove box. Ensure that the interior dimensions of the glove box provide enough space for your tasks without overcrowding.

Ergonomics

An ergonomic design is essential for operator comfort and efficiency. Look for glove boxes with adjustable stands or chairs to accommodate different operators and working heights.

Accessibility

Consider how easy it is to access the interior of the glove box. Some glove boxes have front-loading access, while others may have side or top-loading options. Choose the one that suits your workflow best.

Assess Control Systems

Control systems are vital for maintaining the desired environment inside the glove box. Here are some control features to consider:

Gas Purification and Monitoring

Ensure that the glove box has a reliable gas purification system to maintain the desired gas composition. Monitoring systems should also be in place to alert you to any deviations.

Temperature and Humidity Control

If your application requires precise temperature and humidity control, select a glove box with built-in temperature and humidity controllers.

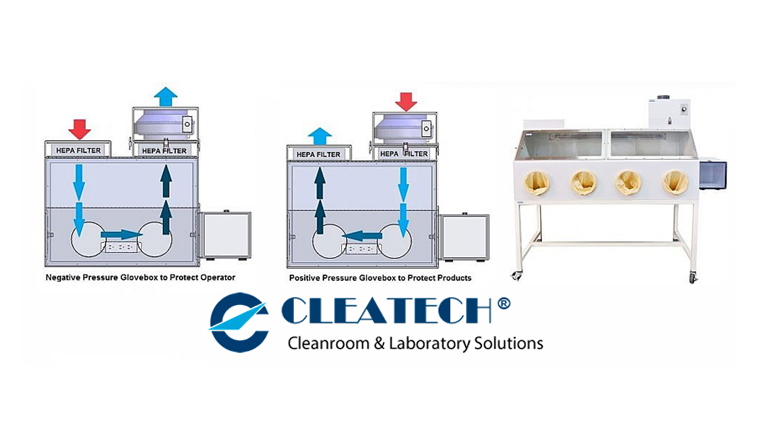

Pressure Control

Some applications may require control over internal pressure. Make sure the glove box can maintain the necessary pressure levels, especially in cleanroom or controlled atmosphere glove boxes.

Safety Features

Safety should always be a top priority when working with glove boxes. Look for the following safety features:

Leak Detection

Glove boxes should have a reliable leak detection system to alert operators to any breaches in the containment.

Emergency Stop

An emergency stop button should be easily accessible in case of any unforeseen issues or emergencies.

Fire Suppression

In applications involving flammable materials, consider glove boxes equipped with fire suppression systems.

Alarm Systems

Alarm systems can notify operators of any deviations from preset conditions, such as changes in gas composition or temperature.

Maintenance and Support

Regular maintenance is essential to keep your glove box functioning correctly. Before making a purchase, inquire about the availability of spare parts and maintenance services. Additionally, check if the manufacturer offers training and technical support to assist with any issues that may arise.

Budget Considerations

While it’s important to invest in a high-quality glove box that meets your needs, it’s equally crucial to consider your budget. Compare the features and capabilities of different glove boxes within your price range. Keep in mind that cheaper options may lack essential safety features or control systems.

Reviews and Recommendations

Before making a final decision, research and read reviews from other users in your field. Their experiences and recommendations can provide valuable insights into the performance and reliability of specific glove boxes.

Plan for Future Needs

Lastly, think about your laboratory’s future needs. Will your research evolve, requiring a different type of glove box or additional features? Consider the long-term flexibility of the glove box you choose to ensure it can adapt to changing requirements.

In conclusion, selecting the right laboratory glove box is a crucial decision that should not be taken lightly. By defining your application requirements, understanding the different types of glove boxes, considering glove material and configuration, evaluating workspace size and layout, assessing control systems and safety features, and factoring in budget considerations, you can make an informed choice that enhances the safety and efficiency of your laboratory work. Remember to plan for future needs to ensure that your investment continues to meet your evolving requirements. With the right glove box from Cleatech LLC you can conduct your research with confidence and precision, knowing that you have chosen the best tool for the job.